Hardening with forging heat – a milestone in energy efficiency

Up to 80% less energy consumption with higher output: With its “hardening with forging heat” process, thyssenkrupp Automotive Technology is setting new standards in the manufacture of racks for electric power steering systems – compared to the conventional process involving cooling and reheating.

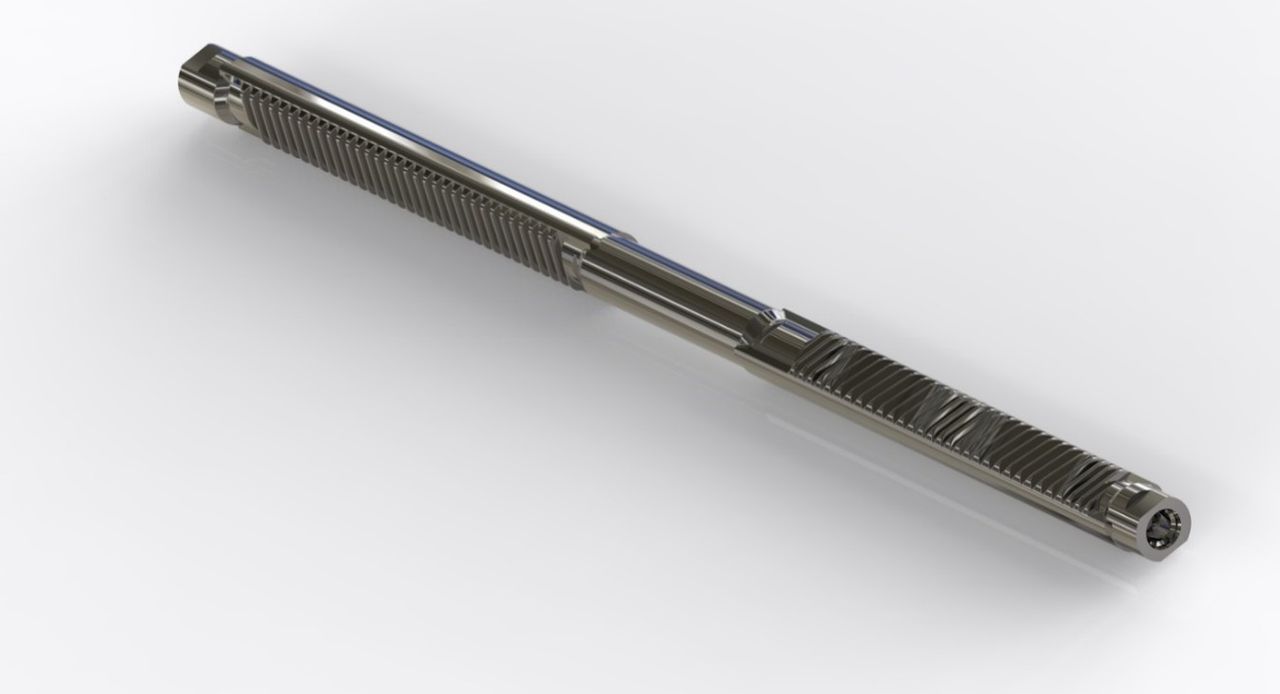

The rack is the central element in the rack EPS steering gear of modern vehicles. It converts the rotational movement of the steering wheel into a linear movement, enabling precise steering of the wheels. Racks with variable tooth profiles are used particularly in sporty or comfort-oriented vehicles. These are manufactured by thyssenkrupp in a forging process and then case-hardened. This enables them to withstand high mechanical loads – especially on the tooth flanks – over the long term.

From the forging process straight to hardening

Until now, hardening forged racks has been an energy-intensive process: after forging, the components first had to cool down, be straightened, and reheated to achieve the desired strength. This process has been fundamentally optimized with the new “hardening with forging heat” production line. The process heat generated during forging is now used directly for hardening – without intermediate cooling and with reduced energy consumption. The result: up to 80% less energy consumption compared to the conventional process – with shorter throughput times and higher output.

thyssenkrupp Automotive Technology is thus improving energy efficiency and competitiveness in component production while reducing energy consumption and the carbon footprint of manufacturing. and is thus strengthening energy efficiency, competitiveness, and the carbon footprint of manufacturing. The more energy-efficient process has been in series production at the thyssenkrupp Automotive site in Schönebeck since 2023 – in parallel with the previous process to ensure ramp-up and variant requirements.

Digitization for maximum transparency

The forging and hardening cell is controlled by proven software that has been used for years in the assembly lines of thyssenkrupp Bilstein Motion Solutions. This software has also recently been rolled out for component manufacturing. It enables intuitive operation, documents all parameter changes in an audit-proof manner, and stores around 1,700 process data points per gearing – a solid basis for quality assurance and continuous process optimization. The software creates end-to-end transparency across the process and forms the basis for stable processes, rapid root cause analysis, and reproducible quality.

Unique process – developed by a strong team with extensive experience in “hot manufacturing processes”

The low-energy process was developed across multiple locations by a small, specialized team from thyssenkrupp's steering works in Eschen (Liechtenstein), Mülheim, and Schönebeck. It has in-depth expertise in manufacturing processes, materials engineering, and joining technologies. The focus is on heat treatment, including the mechanical processing of high-precision steering components, and the process- and plant-related further development of the manufacturing chain.

-to-be-deleted/logo-(header)/thyssenkrupp_logo_claim_d.svg)