Power-up to the next level in engine manufacturing

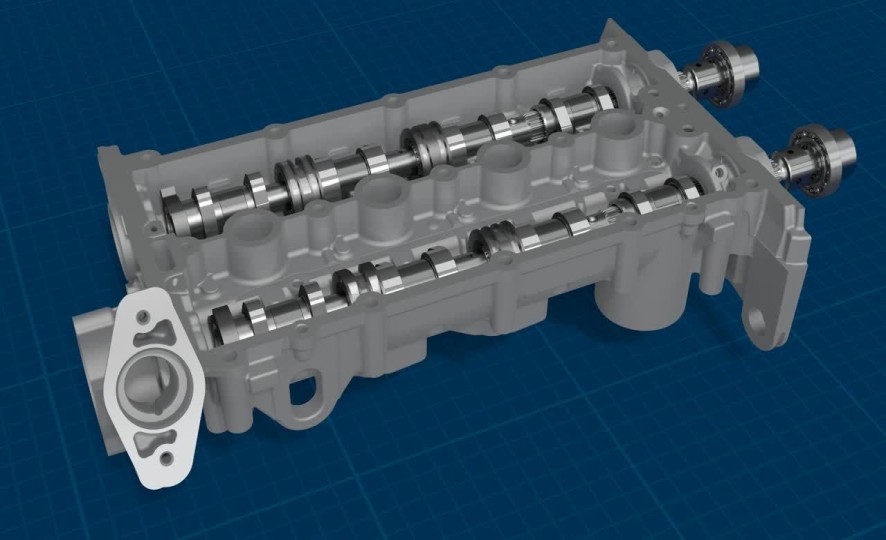

The cylinder head cover with integrated camshafts.

Turning engine installation into childs-play: with the plug & play concept of the completely preassembled cylinder head cover module from thyssenkrupp. The rules of the game have changed... thanks to the integrated camshafts. Precision-fitted, fast and econmomical.

Optimized combustion engine

Cylinder head cover module with integrated camshafts

Weight savings of 30-40% in comparison with a conventional camshaft Transmission of high dynamic and static torques Combination of high-quality camshaft materials with inexpensive tube and endpiece materials that are subject to less loading Lower production effort and expense for further and final processing of the camshafts

Variable valve train system – Concentric Cam

Control of valve phasing or duration: Reduction of emissions; Increase of engine torque and power; Increase exhaust gas temperature Replaceability with conventional camshafts Type 1: phase shifting of single cam lobes on one camshaft Type 2: extension of the cam lifting curve (variable valve opening time)

Cost reduction through alternative assembly concept

2-stage cam profile switching system (two different valve lifts or valve/cylinder deactivation) Combination of different materials possible (cam and shifting groove) Reduced material requirements due to assembly of near net shape components Sliding cam system in combination with cylinder head cover module: Module ready for assembly; Reduces assembly effort at customer side; Reduced system costs; Optional: reduced friction due to unsplit bearings

Electric drive

New assembly concept optimizes function and costs

Modularity and scalability of the whole built (scaling of motor axial length) Innovative architecture enables free material choice for each component according to function (f.e. direct for direct bearing and toothing) 100 % quality management by stroke – force measurement of all press joints Very high potential for weight reduction with dual benefits – translational and rotational Increase in packaging space for integration of additional functions

New assembly concept optimizes function and costs

Stress-related combination of different materials on one shaft Less machining effort due to design close to finished size Less internal tension in the electrical sheets due to combined press and form fit 100% quality data recording for each connection Integration of functions possible by using the available space in the rotor shaft

Videos

-to-be-deleted/logo-(header)/thyssenkrupp_logo_claim_d.svg)