Rethinking Innovation: The “oktasys” Modular System in Plant Manufacturing

With the modular system oktasys, thyssenkrupp Automotive Body Solutions is setting new standards in plant manufacturing. The innovation is based on a consistent lightweight design approach, replacing aluminum with steel as a more powerful alternative – aiming to significantly reduce weight, energy consumption, and costs.

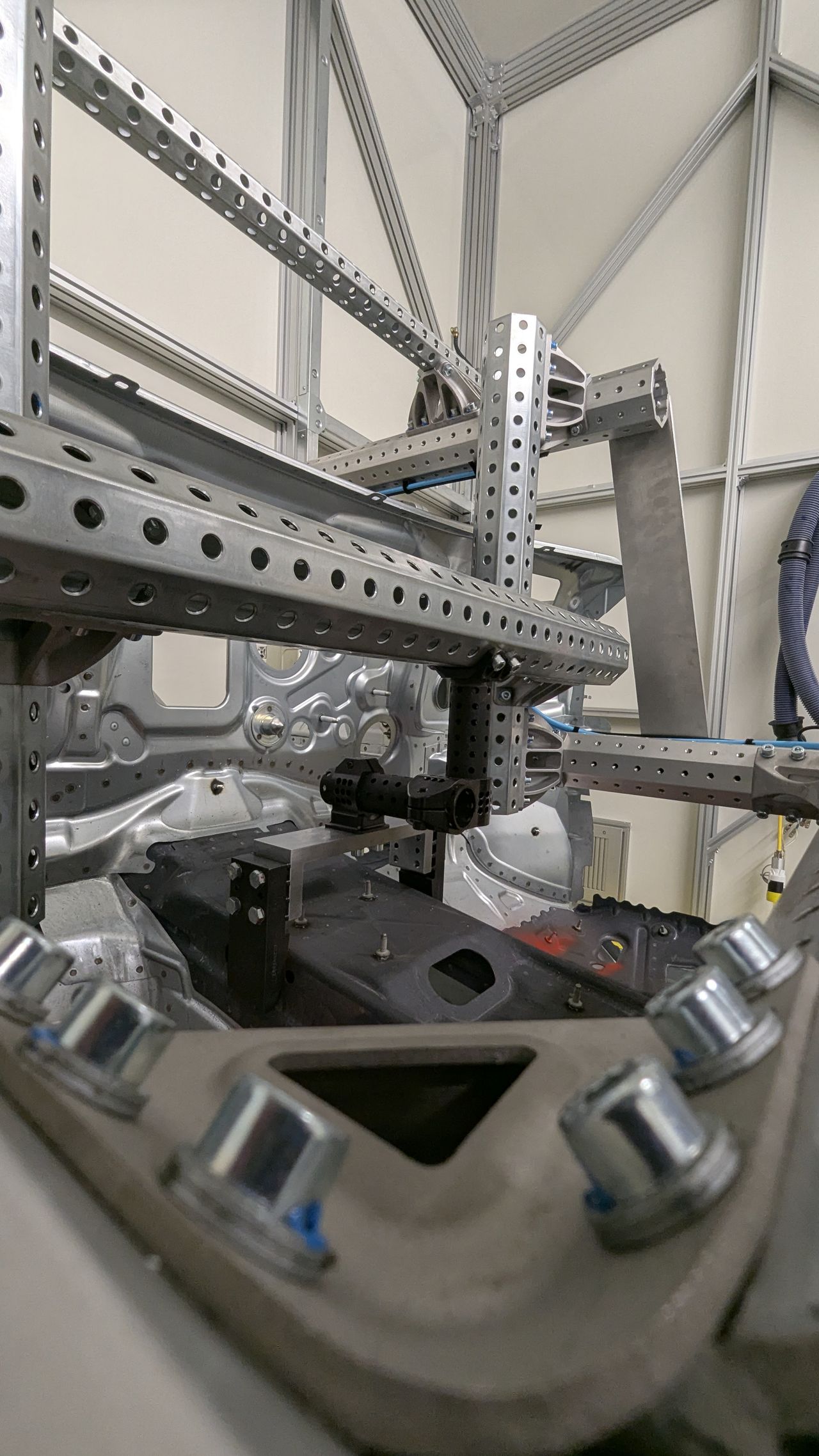

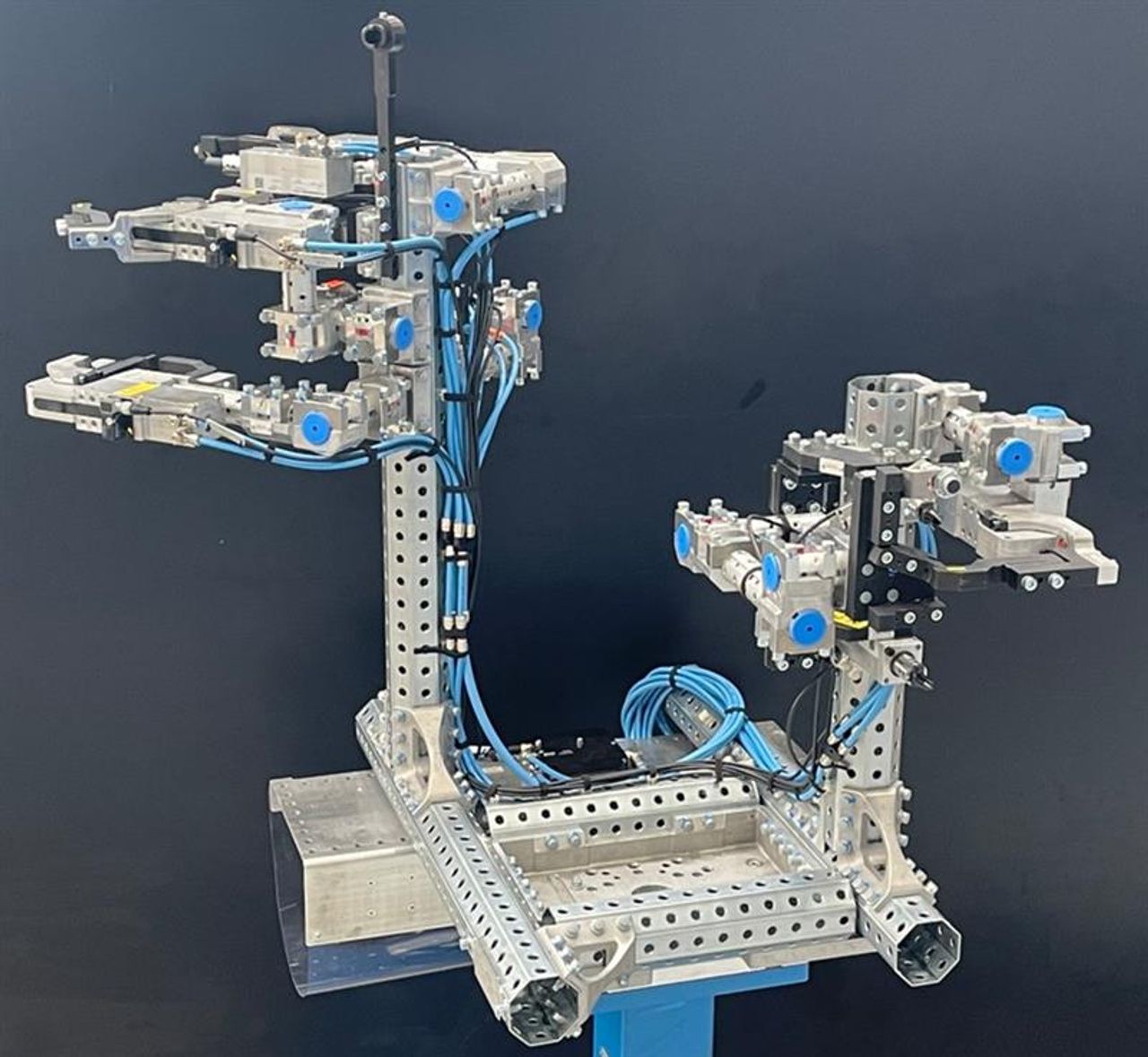

In dynamic car body manufacturing, a wide range of gripper robots is used. However, due to increasing electrification, individual car body parts are becoming heavier. This creates a need for lighter assembly components. This is where oktasys comes in: by using steel profiles, thyssenkrupp Automotive Body Solutions has developed a solution that enables simple, fast, and resource-efficient construction and manufacturing in plant engineering. This allows grippers to handle increasingly heavy components without increasing robot size.

From Concept to Solution

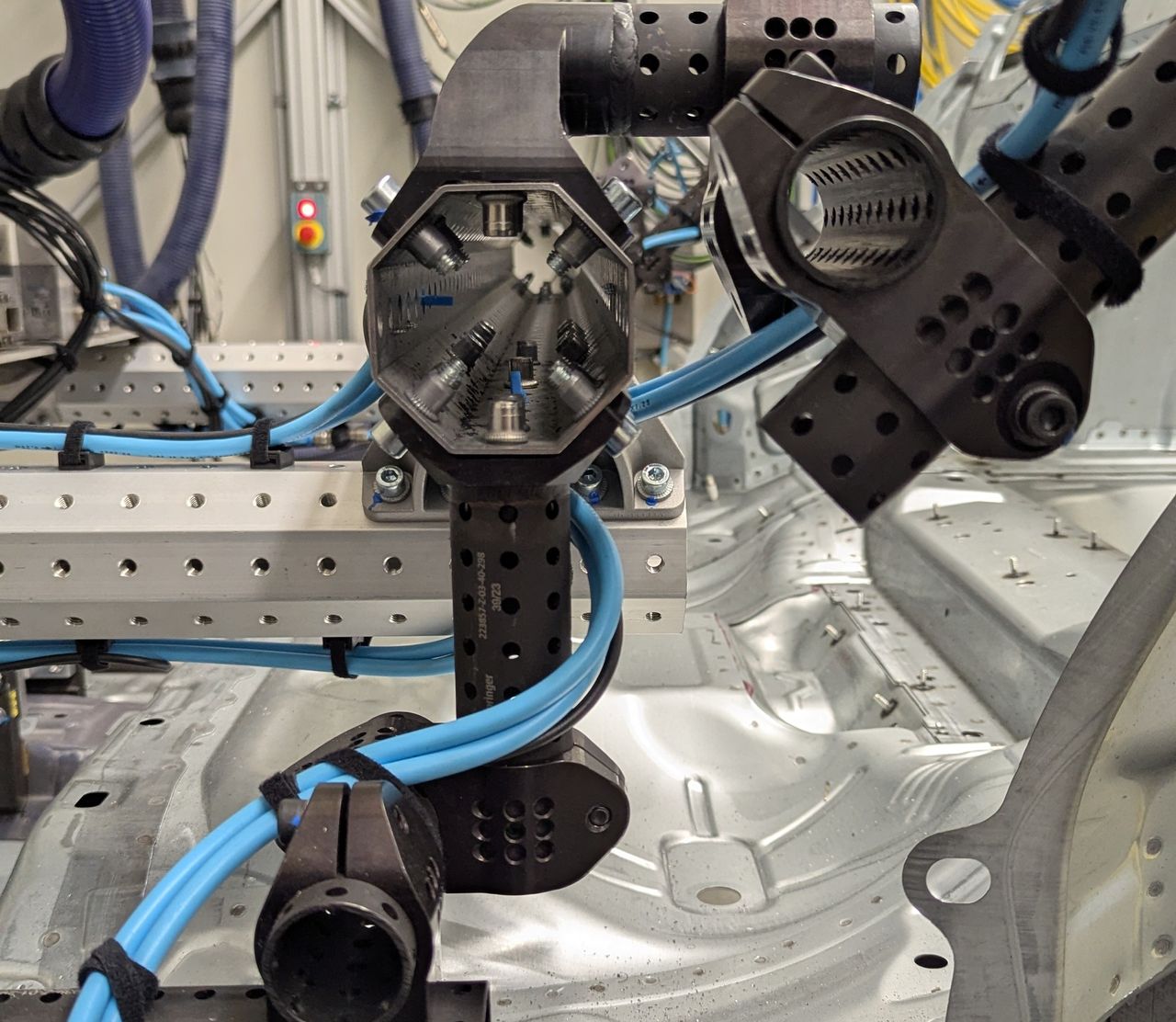

The challenge: For over ten years, grippers at thyssenkrupp Automotive Body Solutions have been made from octagonal profiles. The increasing weight of components exceeded the load capacity of conventional grippers, reducing production efficiency. Under the leadership of Tim Kaub, a mechanical engineer and long-time team leader at the Lockweiler site, an interdisciplinary expert team developed a new solution in collaboration with an external partner.

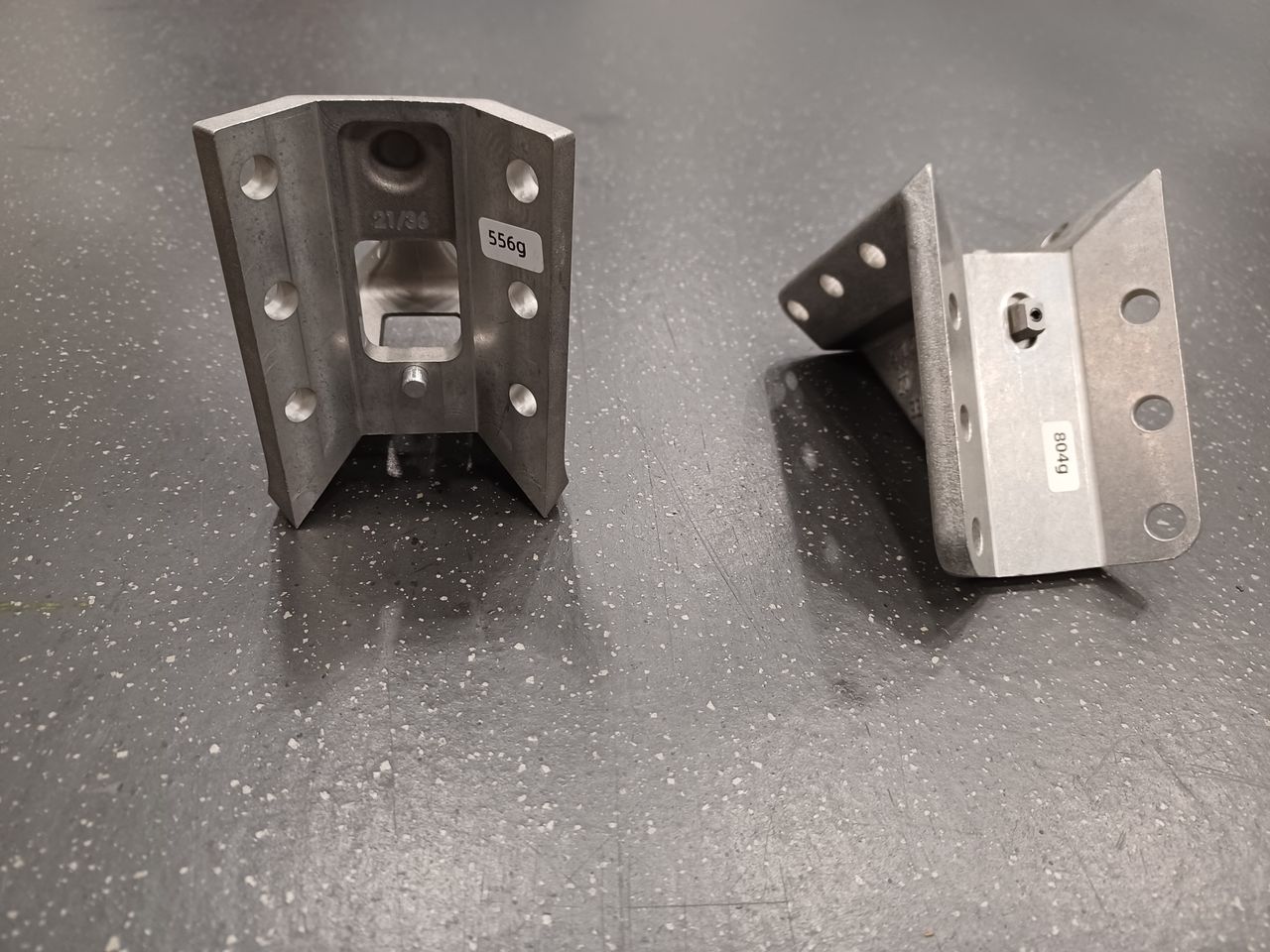

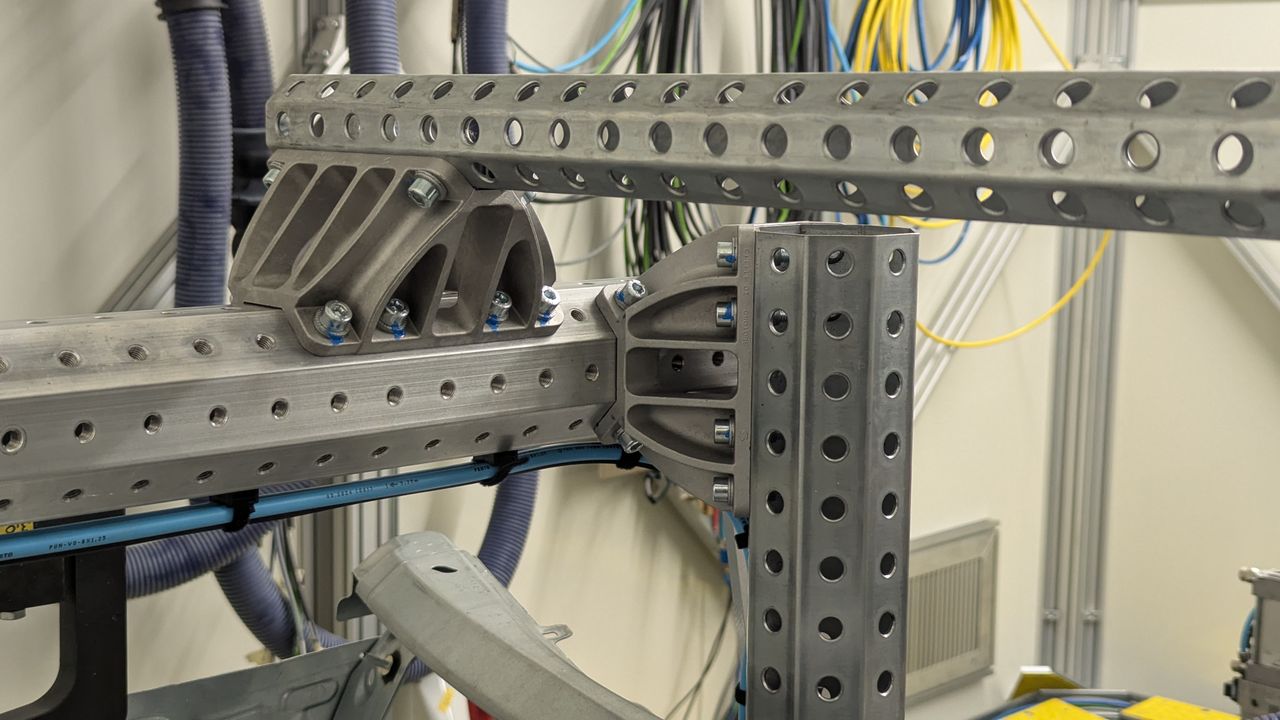

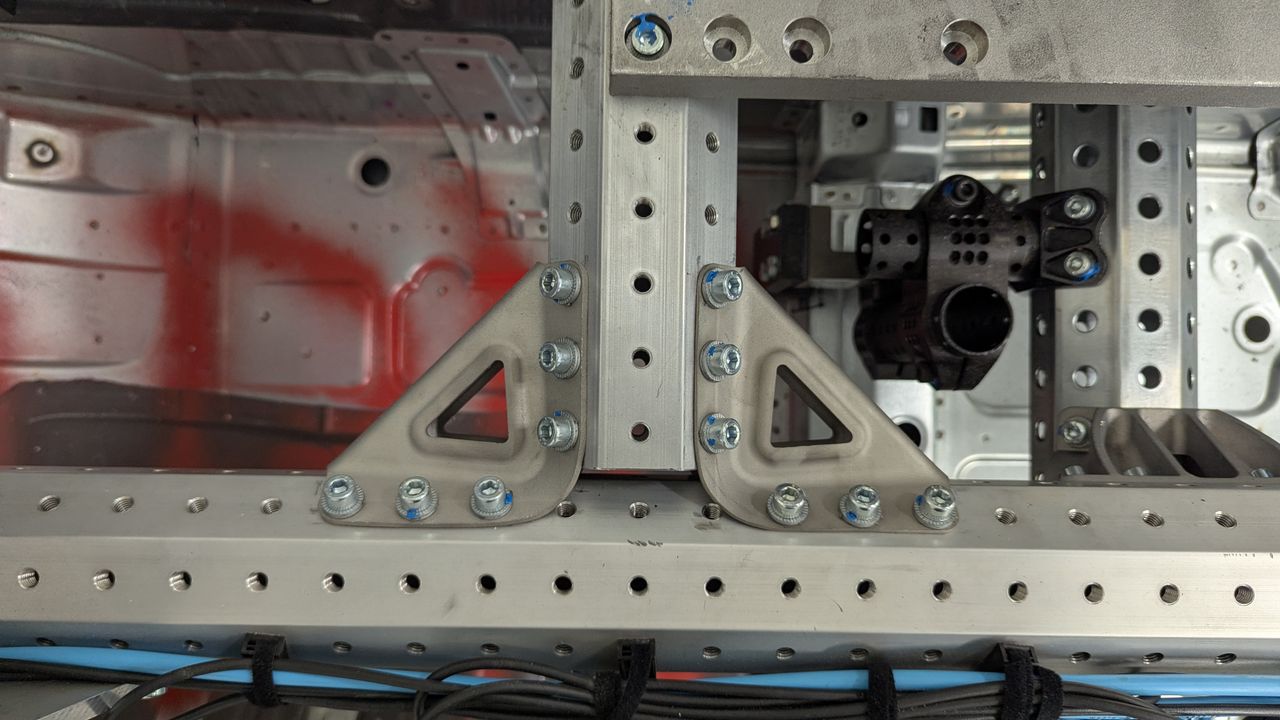

Over a two-year development process, steel was reimagined as a material. As a company with a historical connection to steel, the team tested it first. The material proved convincing due to its strength and the ability to use significantly less material while maintaining the same load capacity. The result: a profile about 25% lighter than comparable competitor products – and just as robust.

Technical Excellence in Detail

Oktasys includes over 100 modules, including specially developed profiles and connectors. The system is fully compatible with all standard octagonal systems and can be flexibly integrated into existing body-in-white lines. Thanks to its modular structure, grippers from various suppliers can be incorporated – a real advantage for OEMs.

The technical requirements are clearly defined:

Higher load capacity with lower weight

Verified static and dynamic load capacity

Optimized tolerances for precise assembly processes

The reduced weight of the grippers allows robots to work faster and handle heavier components.

Integration with Added Value

For OEMs, oktasys means: faster cycle times, lower energy consumption, and greater flexibility. For thyssenkrupp Automotive Body Solutions: a system that integrates seamlessly into existing plants while setting new standards in gripping technology and body construction.

Global Deployment with Local Expertise

Oktasys is already in use at several locations – including Heilbronn, Weinsberg, Mühlacker, and Suzhou in China. Customers from Germany, England, and China rely on the system’s advantages. Further international rollout is planned, aiming to expand the customer base worldwide and flexibly meet individual requirements – from single modules to complete body-in-white systems including commissioning and service.

The Minds Behind oktasys: Tim Kaub and his Team

Tim Kaub, 42, mechanical engineer at thyssenkrupp Automotive Body Solutions, led the development of the oktasys modular system with his team. At the Lockweiler site, Tim is responsible for Components Supply as well as products and systems in final assembly technology. Employees from various departments and disciplines contributed to the development.

Thanks to extensive experience in body construction and close collaboration among all experts – especially with engineering partner Springer Anlagenbau – the innovative solution was developed from the initial idea to successful series production. Today, oktasys is used in production lines worldwide – the result of strong teamwork, technical expertise, and collaborative partnership.

-to-be-deleted/logo-(header)/thyssenkrupp_logo_claim_d.svg)