Tool Shop and Technology Center

Since our foundation in Oberegg, Switzerland in 1971, the Toolshop and Technology Center has been an integral part of thyssenkrupp Presta AG, as part of the Presta Cold Forging (PCF) operating unit.

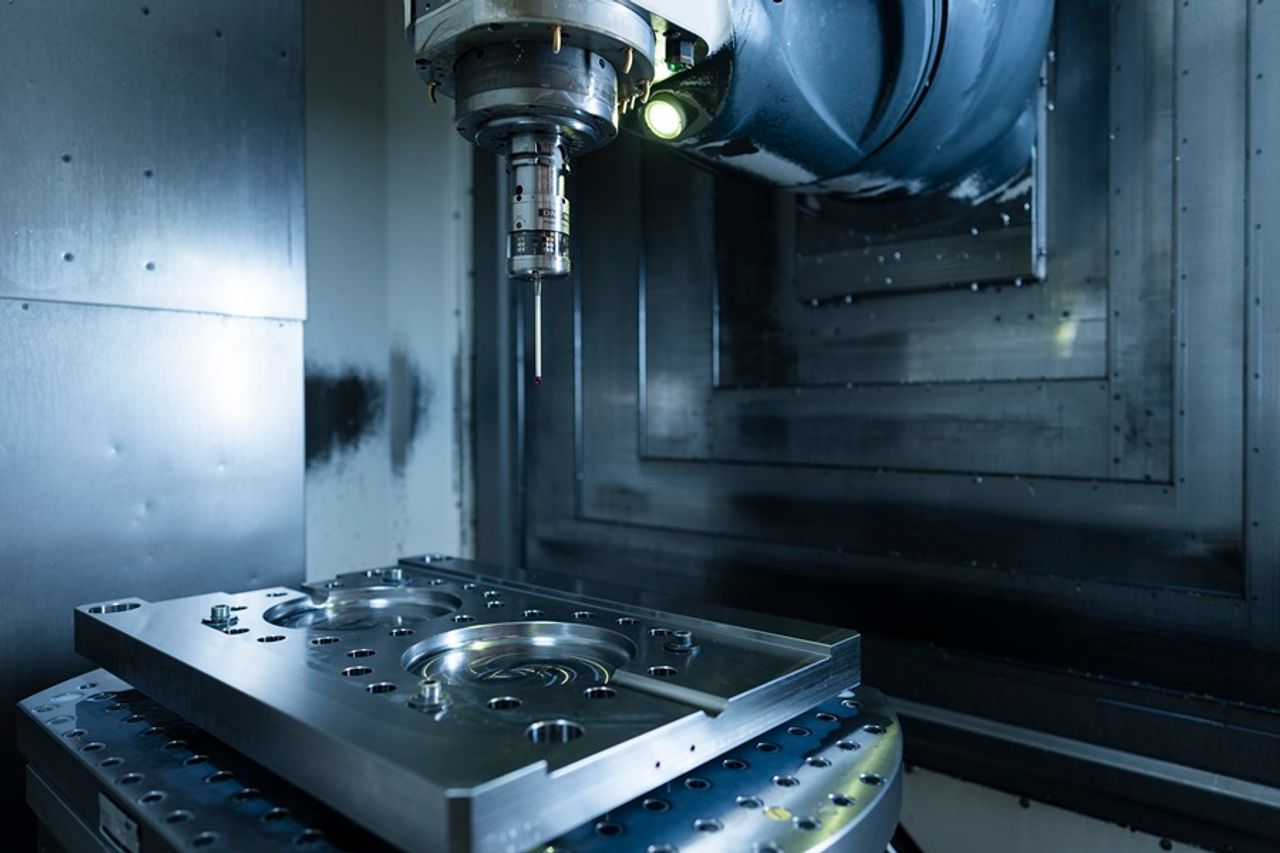

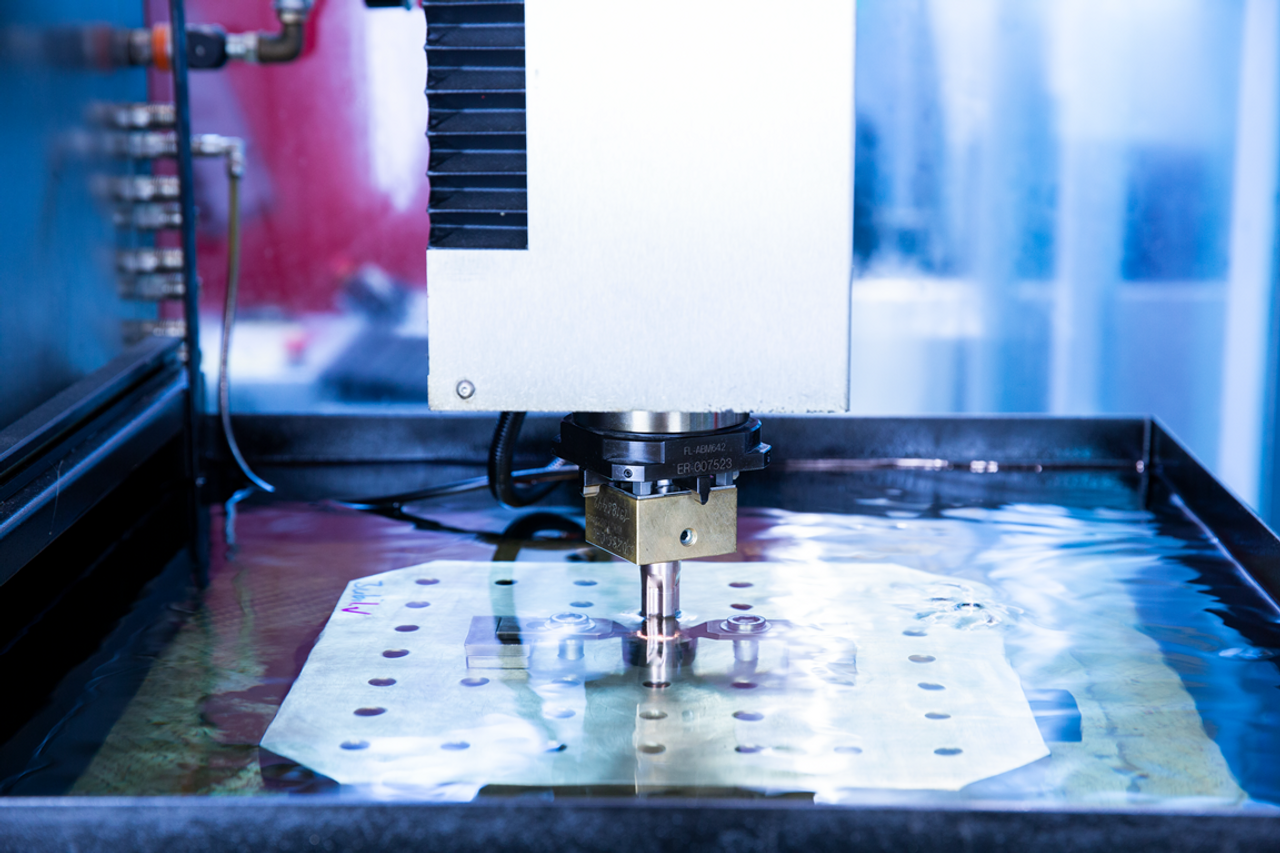

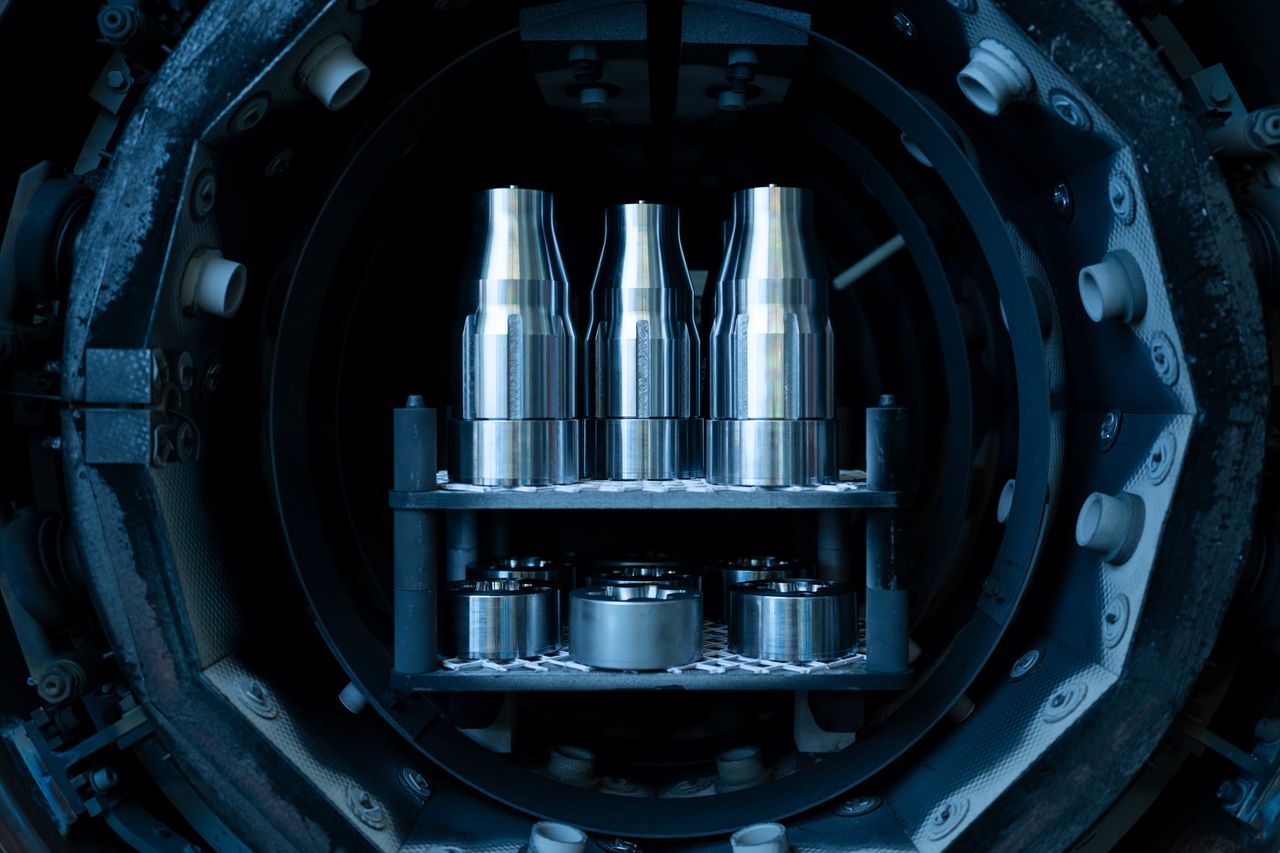

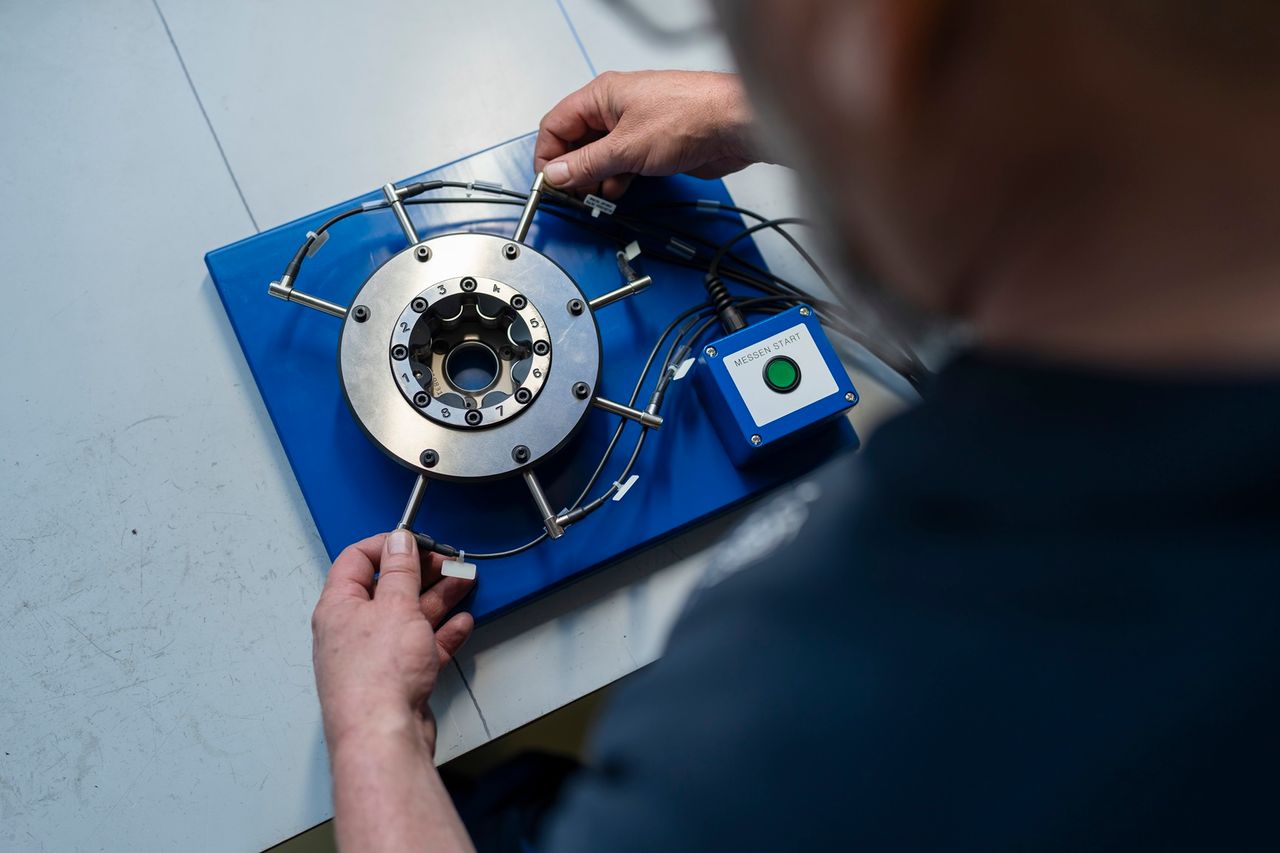

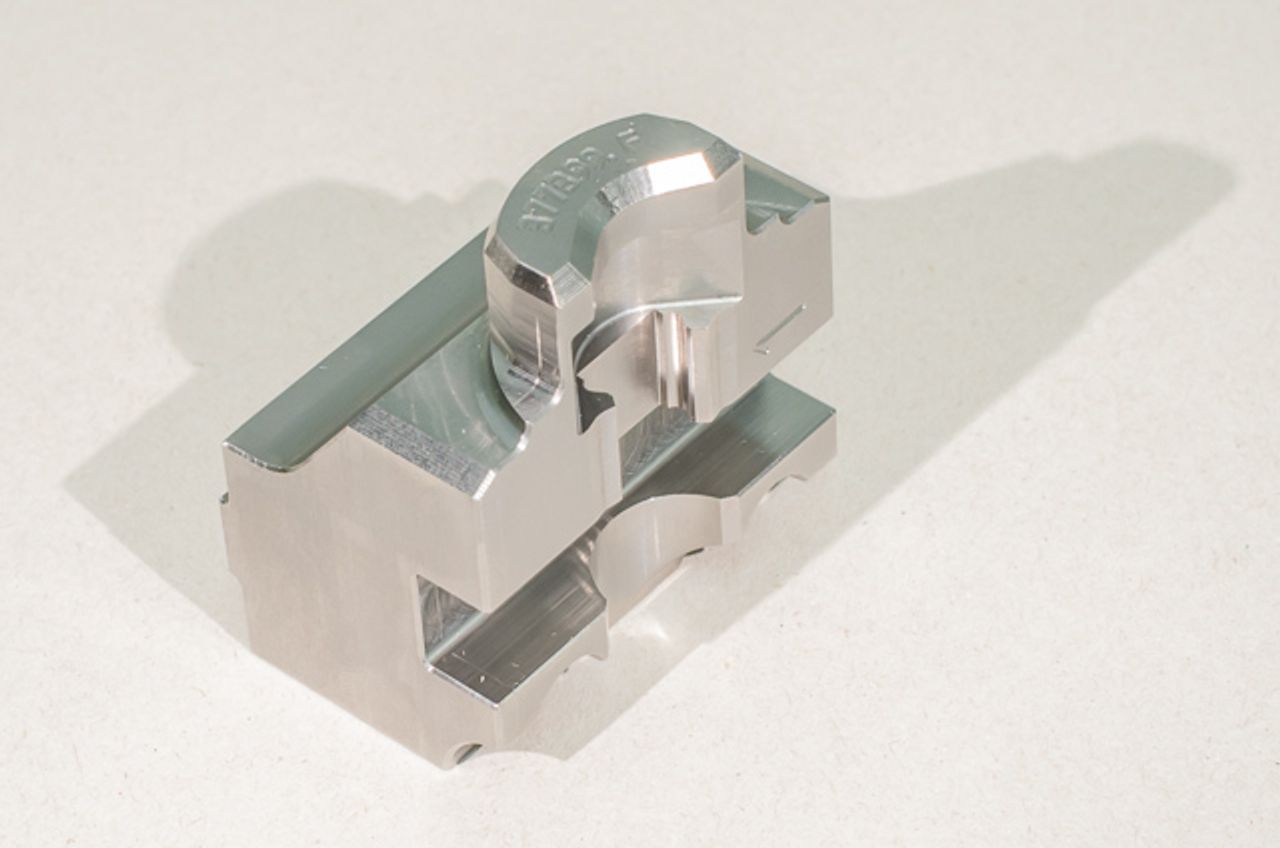

Our focus is on quality, precision and innovation in the production of tools for cold and hot forging, rotary swaging, tube forming, prototype parts, machine parts measurement and test equipment (gauges and measuring devices). As part of thyssenkrupp Presta AG, we combine state-of-the-art technology with our regional roots in the Appenzell area of Switzerland. We specifically promote skilled workers and train our apprentices, particularly tool makers and production mechanics, in our own training workshop. Our production also follows clear principles of sustainable manufacturing, incorporating energy-efficient processes and the conservation of resources.

Our team of around 120 specialists manufactures products for our own use at thyssenkrupp Presta AG, as well as for external customers in the DACH region and Liechtenstein. Our efficient processes and automated production technologies ensure consistent quality for automotive and non-automotive applications, as well as for contract manufacturing in the industrial sector.

Thanks to our high level of vertical integration, we offer our customers maximum efficiency and quality – all services from a single source – from planning and production to delivery. This enables short response times, maximum flexibility and seamless realisation of technical requirements.

Our extensive product portfolio is designed to meet the diverse requirements of the automotive and non-automotive industries. It comprises solutions for a wide range of applications and is divided into six segments:

Find the latest information on our activities here, as well as details of our recent successes.

-to-be-deleted/logo-(header)/thyssenkrupp_logo_claim_d.svg)