thyssenkrupp AG is a global industrial and technology company headquartered in Essen, Germany, with around 100,000 employees in 48 countries. thyssenkrupp AG has consolidated its activities into five segments: Automotive Technology, Decarbon Technologies, Materials Services, Steel Europe and TKMS.

Four business units operate in the Automotive Technology segment: Bilstein Motion Solutions, Presta Dynamic Components, Aftermarket Group and Forged Technologies. The Presta Dynamic Components business unit comprises 18 plants worldwide, around 6,000 employees and three product lines: Drivetrain Components, eA/C Compressor as well as Cold Forging and Steering Components.

As Presta Cold Forging, we represent the origin of Presta AG and are among the leading automotive suppliers in the field of forging and machining. Together, we are setting new standards in the automotive industry and actively shaping the mobility of tomorrow.

Thanks to our international presence, represented by the Presta Cold Forging plants in Puebla (Mexico), Changzhou (China), Eschen (Liechtenstein), Meseritz (Poland) and Indianapolis (USA), we operate globally in all relevant markets as a company in the field of forging. In addition, our highly specialized tool shop and technology center in Oberegg (Switzerland) focuses on manufacturing high-precision tools in the micrometer accuracy range.

This global structure enables us to meet the most diverse needs of our customers and offer high-quality products and first-class customer support. The regional distribution of our teams ensures that our customers always have a local contact.

Information about our Locations

Our Chinese plant focuses on producing single-stage and multi-stage vertical pressed products, as well as similar product finish levels as those from our Mexican site. At this site we manufacture components primarily for the Chinese market, as well as for other Asian countries.

Our plant in Eschen is the heart of our company and represents the headquarters and development center. Here, we bring together our expertise and innovations to develop and optimize our entire cold forging portfolio, with a particular focus on horizontal and vertical presses. We offer customized solutions that meet the highest quality standards. Our location in Eschen stands for innovation, reliability and customer satisfaction.

The subsidiary in Puebla focuses on the production of high-quality single-stage and multi-stage vertical forged products as well as supplementary manufacturing processes such as machining operations and heat treatments.

We mainly supply customers in Mexico and the USA from Puebla, providing a quick, reliable and high-quality service. Our Puebla facility is also capable of producing tooling in order to ensure fast and flexible production.

In Poland, we specialize in machining and assembly activities. Our focus is on precise finishing processes, including soft and hard machining, to meet the highest quality standards. We aim to deliver ready for assembly parts efficiently to and from Europe.

Our Oberegg plant specializes in the production of high-quality forging tools, mold-making components, prototypes and CNC components. We also manufacture a range of measuring equipment and gauges, from individual items to complete gauges, in-house. After careful testing and certification, the measuring equipment and gauges are delivered directly to our plants worldwide.

Our sales office in Indianapolis is the strategic center for our activities in North, Central and South America. Located close to the heart of the North American automotive industry, this site allows us to work closely with our partners and customers on-site.

As a provider of cold forged system solutions for our customers, we are more than just a component supplier. We act as a development partner and use our know-how and experience to ensure that we always find the best solutions for our customers.

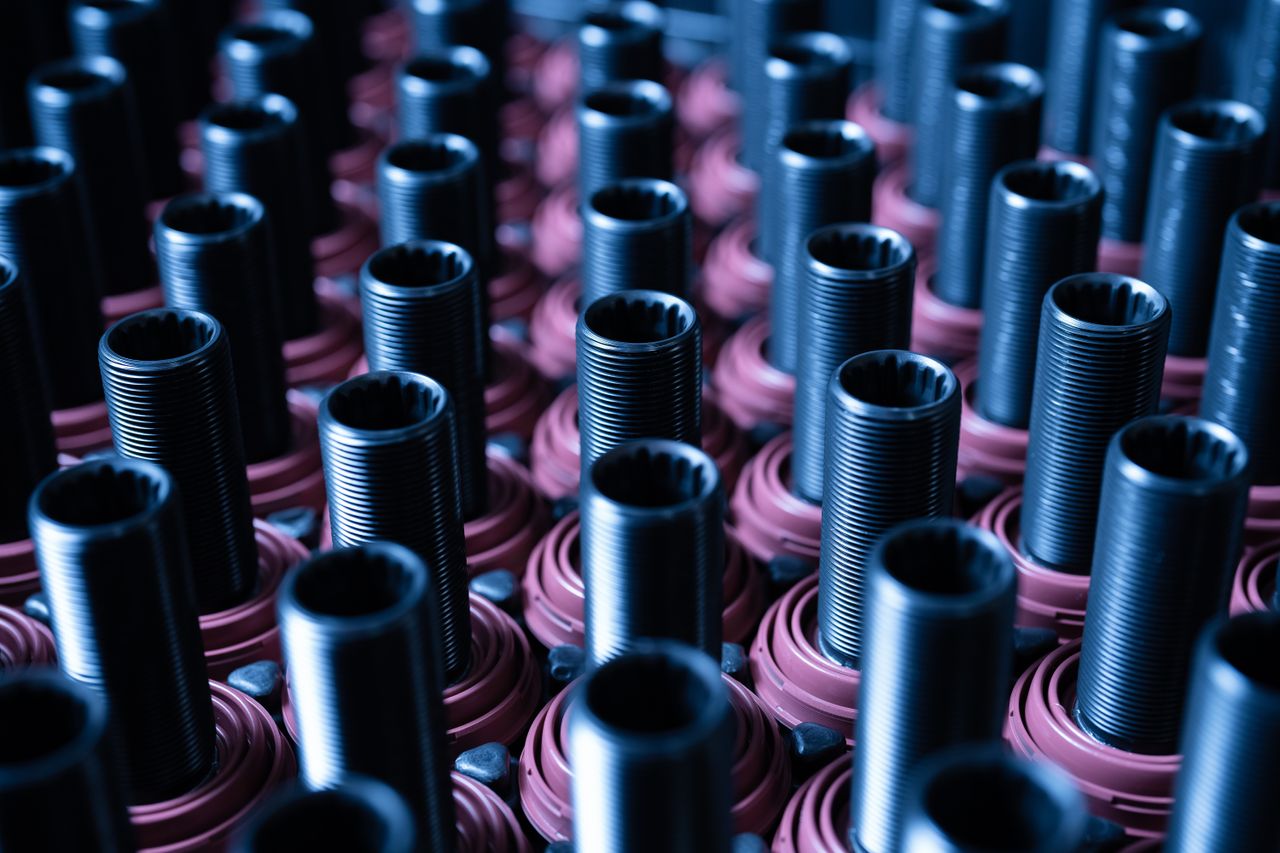

Our product portfolio is targeted towards the most diverse requirements of cars and trucks as well as for other industrial applications and is divided into five segments. In addition to steering components, the core business also includes parts for the driveline. These areas are based on our extensive expertise in forging technology, which makes them our most important focus areas. Additionally, we offer our customers a comprehensive range of solutions for braking components, commercial vehicles, seating components and non-automotive components.

Technology

Technology

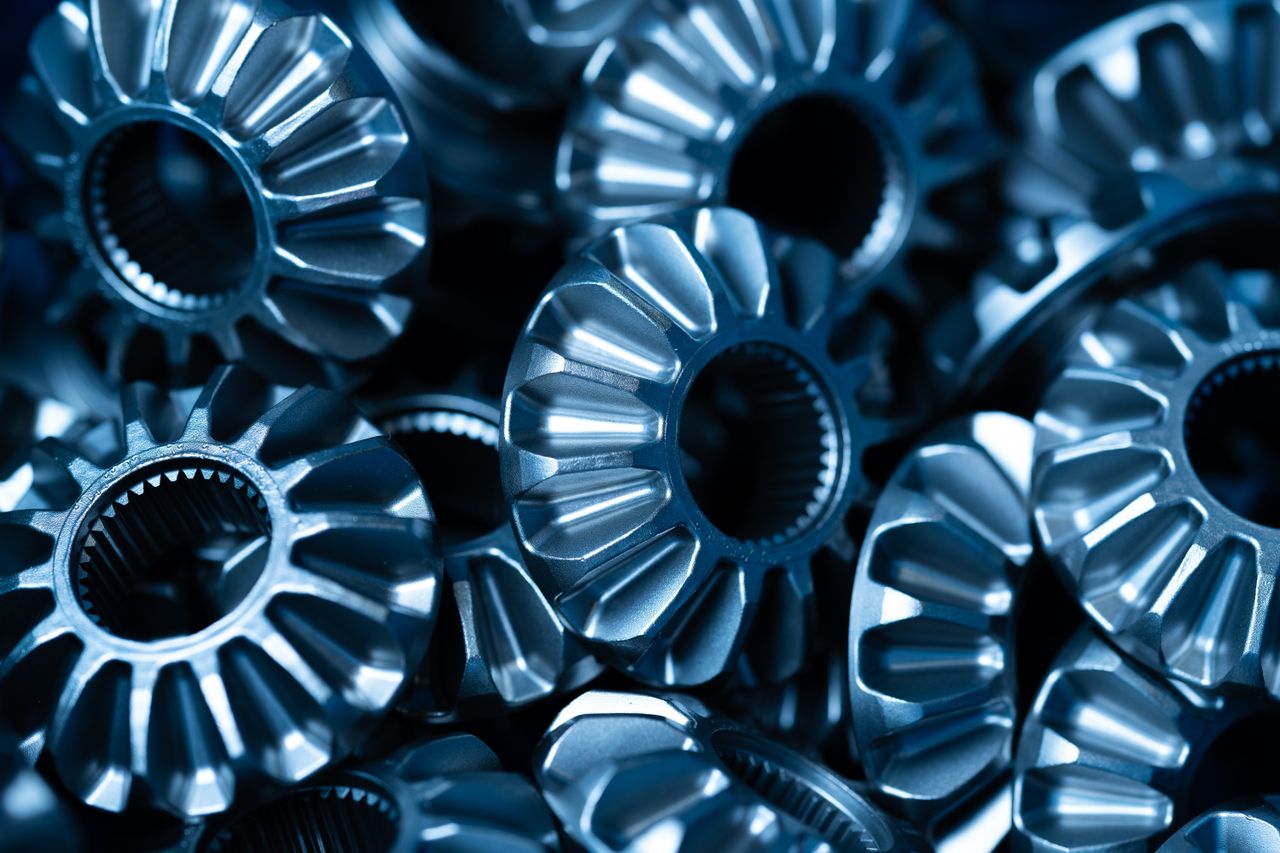

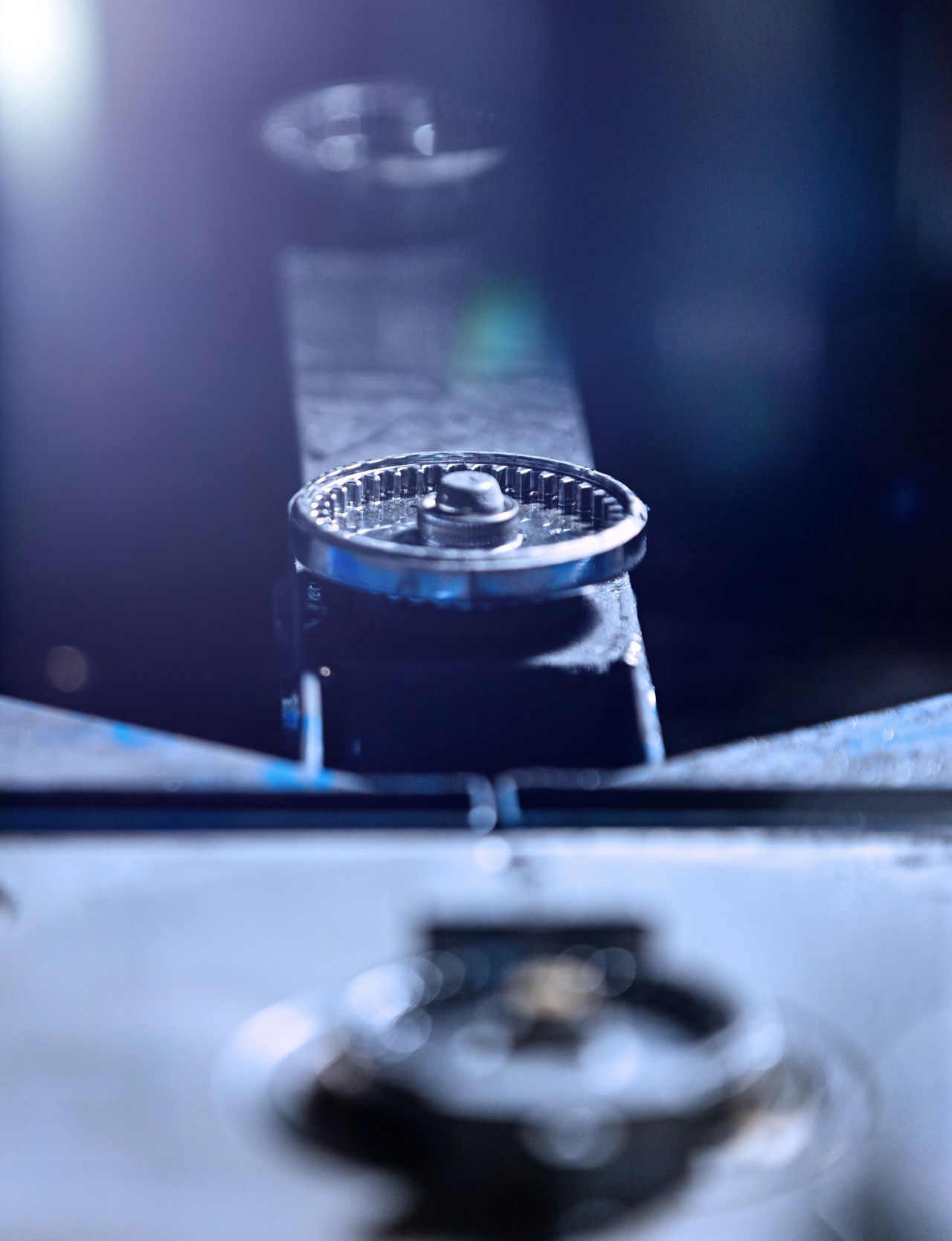

Cold forging is a process that uses wire or bar material made from various grades of steel. In cold forging, a blank is forged at room temperature using special tools and very high forces. By forging the material at low temperatures, we can improve its strength and achieve high dimensional accuracy.

With over 80 years' experience in cold forging, we combine in-depth expertise with maximum precision to provide individual solutions for our customers. We are committed to maintaining the highest quality and safety standards.

Using state-of-the-art forging technologies and proven processes, we produce cold forged parts that are either ready for assembly or almost ready for assembly, minimizing or even completely eliminating the need for downstream processes. This guarantees efficient production and reliable results tailored to your individual requirements.

Advantages of cold forging:

Optimum material utilization

High static and dynamic strength due to uninterrupted grain flow

Production of net-shape and near-net-shape parts

Economical, precise and high volume production of complex parts

Find the latest information on our activities here, as well as details of our recent successes.

Presta Cold Forging - Driving Innovation worldwide

Download

America

- IATF 16949 Certificate_Mexico (2023-2026) V2

pdf | 166.28 kb

China

- IATF 16949 Certificate_Changzhou (2023-2026)

pdf | 263.06 kb

Europe

- IATF 16949 Certificate_Eschen Oberegg Budapest (2023-2026) en

pdf | 628.89 kb - ISO50001_MSA_SGS_20221118

pdf | 1990.99 kb - ThyssenKrupp Presta AG - Zertifikat - ISO 14001 - EN 24-27

pdf | 596.92 kb - ThyssenKrupp Presta AG - Zertifikat - ISO 45001 - EN 24-27

pdf | 597.72 kb

Contact

thyssenkrupp Presta AG

Presta Cold Forging (PCF)

Essanestrasse 10

9492 Eschen, Liechtenstein

Phone: +423 377 2244

E-Mail: coldforging@thyssenkrupp-automotive.com

-to-be-deleted/logo-(header)/thyssenkrupp_logo_claim_d.svg)